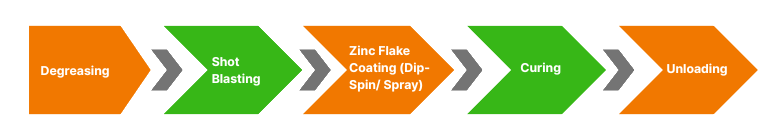

Zinc Flake Coating Equipment - Dip & Spin Machine / Spray Type Machine

Zinc Flake Coating Lines with Dip-Spin & Spray Technology

Suntech’s Zinc Flake Coating systems offer both Dip-Spin and Spray Application technologies, engineered for the mass finishing of small to medium-sized fasteners and parts. Our automated systems ensure consistent film thickness, excellent adhesion, and superior corrosion resistance without hydrogen embrittlement.

Zinc Flake Coating Plant Manufacturer in India with Dip-Spin and Spray Application Technology

Suntech Industrial Solutions delivers zinc flake coating in India through advanced Dip-Spin and Spray coating systems engineered for high-corrosion resistance applications. As a trusted zinc flake coating plant manufacturer, we design and support fully integrated coating plants that ensure uniform thickness, excellent adhesion, and long-lasting protection without the risk of hydrogen embrittlement—making our solutions ideal for fasteners and critical automotive components.

Purpose and Benefits

Zinc flake coatings form a micro-layered barrier that offers long-lasting sacrificial protection, even in harsh environments. The non-electrolytic nature avoids hydrogen embrittlement, making it ideal for high-tensile parts. Whether applied via Dip-Spin for high-volume small parts or Spray Systems for larger or complex geometries, the coating delivers >1000 hours of salt spray resistance and complies with RoHS, REACH, and global automotive standards.

Industries & Products

Common in automotive, wind energy, and construction sectors for high-tensile fasteners, brake components, bolts, nuts, and washers—especially where >1000-hour salt spray resistance and non-embrittling coatings are required.

Configuration & Capabilities

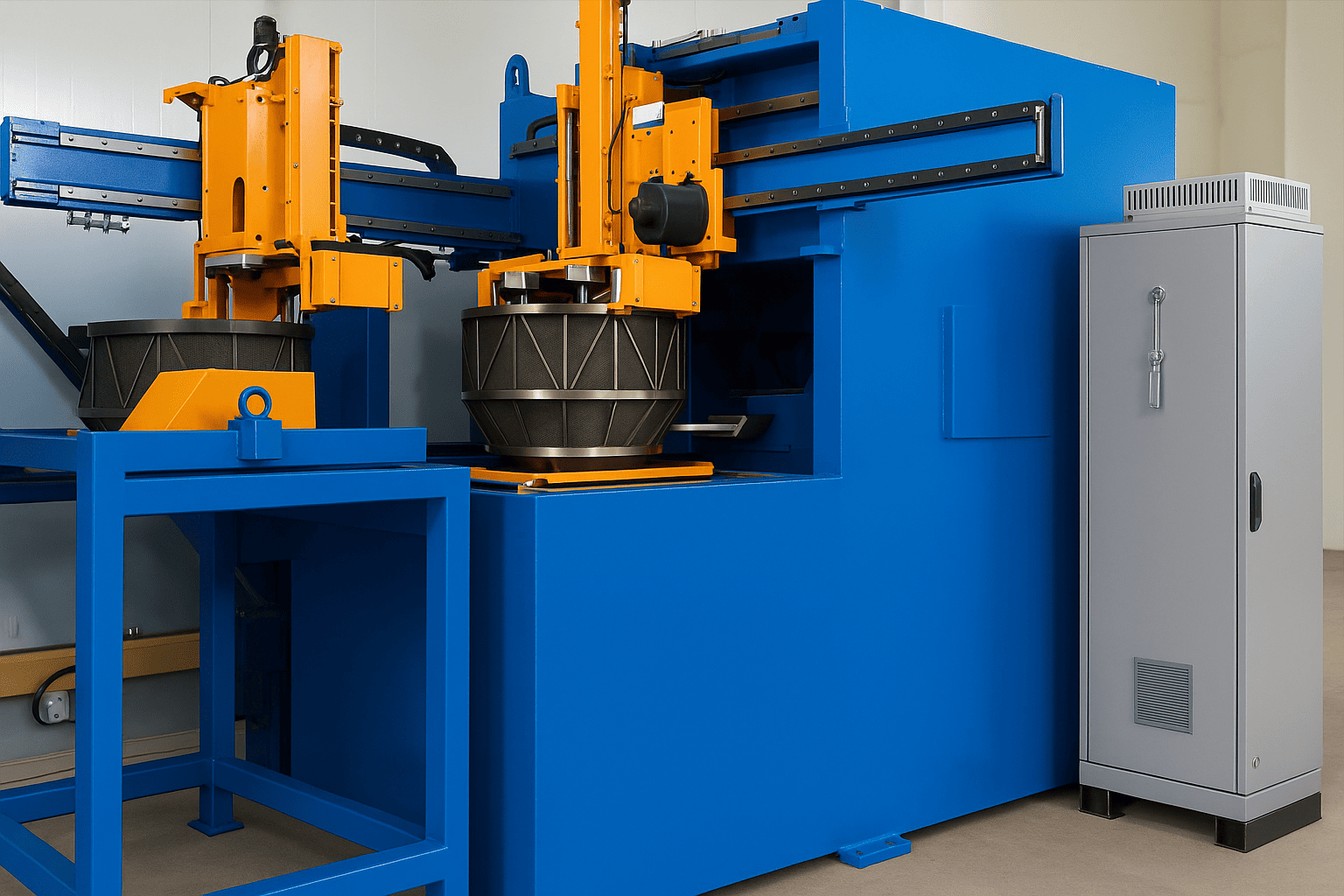

Our systems are modular and customizable to suit volume, part geometry, and application method:

- Dip-Spin Systems: Programmable basket speed, drain, and cycle control

- Spray Booths: Robotic or manual application with fine atomization control

- Curing Ovens: Hot air or IR tunnels for precise thermal profiles

- Automation: Automatic part feeding, recipe management, and robotic unload

- Environmental Controls: Closed-loop exhaust and fume scrubbers

Notable features:

- Dual or multi-layer coating support (base + topcoat)

- SCADA-ready controls with digital recipe tracking

- Compact footprint with high throughput efficiency

Purpose and Benefits

Zinc flake coatings form a micro-layered barrier that offers long-lasting sacrificial protection, even in harsh environments. The non-electrolytic nature avoids hydrogen embrittlement, making it ideal for high-tensile parts. Whether applied via Dip-Spin for high-volume small parts or Spray Systems for larger or complex geometries, the coating delivers >1000 hours of salt spray resistance and complies with RoHS, REACH, and global automotive standards.

Industries & Products

Common in automotive, wind energy, and construction sectors for high-tensile fasteners, brake components, bolts, nuts, and washers—especially where >1000-hour salt spray resistance and non-embrittling coatings are required.

Configuration & Capabilities

Our systems are modular and customizable to suit volume, part geometry, and application method:

- Dip-Spin Systems: Programmable basket speed, drain, and cycle control

- Spray Booths: Robotic or manual application with fine atomization control

- Curing Ovens: Hot air or IR tunnels for precise thermal profiles

- Automation: Automatic part feeding, recipe management, and robotic unload

- Environmental Controls: Closed-loop exhaust and fume scrubbers

Notable features:

- Dual or multi-layer coating support (base + topcoat)

- SCADA-ready controls with digital recipe tracking

- Compact footprint with high throughput efficiency

Explore Our Proven Track Record

From decorative trims to functional engine components, our surface finishing solutions have powered performance and elevated design.