Continuous Heat Treatment Furnace

Continuous Heat Treatment Furnaces for Metallurgical Performance

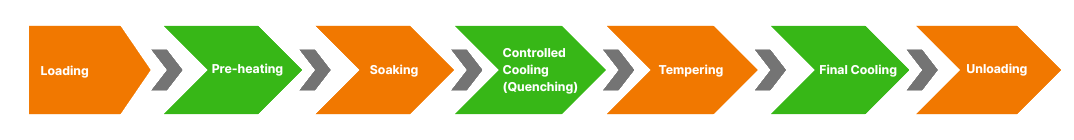

Suntech’s continuous heat treatment furnaces are engineered for precise thermal cycles involving hardening, annealing, tempering, and stress relieving. Designed for high-throughput metallurgical operations, these systems ensure consistent material properties with exact thermal profiling.

Continuous Heat Treatment Furnace Manufacturer delivering furnaces engineered for superior metallurgical performance.

As a continuous heat treatment furnace manufacturer, Suntech engineers advanced furnace systems designed for precise thermal cycles including hardening, annealing, tempering, and stress relieving. Built for high-throughput metallurgical operations, our continuous heat treatment furnaces ensure consistent material properties through accurate thermal profiling and controlled process conditions.

Purpose and Benefits

Heat treatment is essential to tailor mechanical properties such as strength, toughness, and hardness. A continuous furnace enables consistent throughput, tight temperature control, and energy-efficient heating. It eliminates batch delays, reduces manpower, and ensures reproducibility—critical for automotive and tooling applications.

Industries & Products

Used in automotive and industrial tooling sectors for treating gears, shafts, springs, chains, and bearing components. Especially suited for high-volume parts requiring consistent hardness and metallurgical integrity.

Configuration & Capabilities

Available in mesh belt, roller hearth, or pusher-type configurations. Includes SCADA-integrated temperature zones, nitrogen/atmosphere control, and rapid cooling/quench systems.

Purpose and Benefits

Heat treatment is essential to tailor mechanical properties such as strength, toughness, and hardness. A continuous furnace enables consistent throughput, tight temperature control, and energy-efficient heating. It eliminates batch delays, reduces manpower, and ensures reproducibility—critical for automotive and tooling applications.

Industries & Products

Used in automotive and industrial tooling sectors for treating gears, shafts, springs, chains, and bearing components. Especially suited for high-volume parts requiring consistent hardness and metallurgical integrity.

Configuration & Capabilities

Available in mesh belt, roller hearth, or pusher-type configurations. Includes SCADA-integrated temperature zones, nitrogen/atmosphere control, and rapid cooling/quench systems.

Explore Our Proven Track Record

From decorative trims to functional engine components, our surface finishing solutions have powered performance and elevated design.