Phosphating Line

Phosphating Systems for Surface Conditioning and Paint Bonding

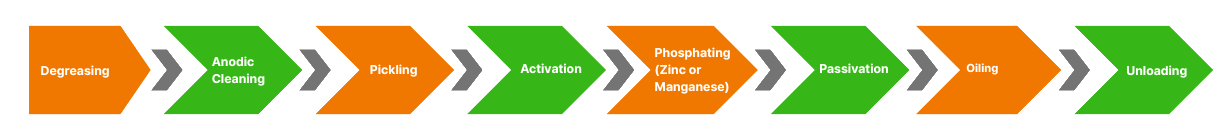

Suntech’s phosphating lines support industrial-grade surface pretreatment for parts requiring enhanced paint adhesion, wear resistance, and corrosion inhibition. We build systems for both zinc and manganese phosphate processes, along with tailored activation and oiling stages.

Phosphating Line systems for surface conditioning and enhanced paint bonding.

Suntech’s phosphating line systems support industrial-grade surface pretreatment for components requiring enhanced paint adhesion, improved wear resistance, and effective corrosion inhibition. Our phosphating line solutions are engineered for both zinc and manganese phosphate processes, with tailored activation and oiling stages to ensure consistent coating quality and process reliability.

Purpose and Benefits

Phosphating improves paint bonding, reduces friction, and adds wear resistance. Zinc phosphate is ideal for corrosion prevention under paint, while manganese phosphate is used for parts under high load/stress due to its lubricity. The process enhances mechanical properties while also preparing surfaces for further treatments.

Industries & Products

Common applications include fasteners, brackets, chassis parts, and structural hardware for automotive, aerospace, defense, and construction industries. Zinc-Nickel is widely used in EV components and fuel systems for its superior corrosion performance.

Configuration & Capabilities

Plants feature heated tanks with agitation, spray or immersion configurations, and Sludge separators and oil skimmers. Available with drying ovens.

Notable features:

- Fully automated crane systems with PLC/SCADA control

- Optional ultrasonic cleaning and pickling

- Integrated passivation and post-phosphating oiling stations

- Robust material handling and dosing systems

Purpose and Benefits

Phosphating improves paint bonding, reduces friction, and adds wear resistance. Zinc phosphate is ideal for corrosion prevention under paint, while manganese phosphate is used for parts under high load/stress due to its lubricity. The process enhances mechanical properties while also preparing surfaces for further treatments.

Industries & Products

Common applications include fasteners, brackets, chassis parts, and structural hardware for automotive, aerospace, defense, and construction industries. Zinc-Nickel is widely used in EV components and fuel systems for its superior corrosion performance.

Configuration & Capabilities

Plants feature heated tanks with agitation, spray or immersion configurations, and Sludge separators and oil skimmers. Available with drying ovens.

Notable features:

- Fully automated crane systems with PLC/SCADA control

- Optional ultrasonic cleaning and pickling

- Integrated passivation and post-phosphating oiling stations

- Robust material handling and dosing systems

Explore Our Proven Track Record

From decorative trims to functional engine components, our surface finishing solutions have powered performance and elevated design.