Galvanizing Equipment

Hot Dip Galvanizing Plants for Corrosion-Proof Metal Protection

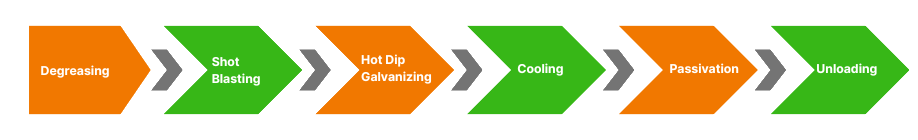

Suntech designs galvanizing plants that meet global standards. From surface cleaning to fluxing and zinc immersion, every process is engineered for optimal coating adhesion, thickness control, and environmental compliance.

Hot Dip Galvanizing Plants for Corrosion-Proof Metal Protection

Suntech designs hot dip galvanizing plants engineered to meet global quality and environmental standards. From surface cleaning and fluxing to controlled zinc immersion, every stage of our hot dip galvanizing plants is optimized for superior coating adhesion, precise thickness control, and long-term corrosion protection, ensuring consistent performance across demanding industrial applications.

Purpose and Benefits

Galvanizing offers a metallurgically bonded coating that provides robust protection even in highly corrosive outdoor environments. Unlike paint, it forms an intermetallic layer with the base steel that resists mechanical damage and corrosion creep. It significantly reduces maintenance cost over the life of a structure.

Industries & Products

Common in railway, windmill fasteners, transmission towers, pipelines. Essential for civil engineering, construction, and heavy machinery.

Configuration & Capabilities

Customizable tanks with fume extraction, flux filtration, zinc dross management, and robotic loading arms.

- Dip-Spin Systems: Programmable basket speed, drain, and cycle control

- Spray Booths: Robotic or manual application with fine atomization control

- Curing Ovens: Hot air or IR tunnels for precise thermal profiles

- Automation: Automatic part feeding, recipe management, and robotic unload

- Environmental Controls: Closed-loop exhaust and fume scrubbers

Notable features:

- Dual or multi-layer coating support (base + topcoat)

- SCADA-ready controls with digital recipe tracking

- Compact footprint with high throughput efficiency

- Dross removal and zinc recovery systems

Purpose and Benefits

Galvanizing offers a metallurgically bonded coating that provides robust protection even in highly corrosive outdoor environments. Unlike paint, it forms an intermetallic layer with the base steel that resists mechanical damage and corrosion creep. It significantly reduces maintenance cost over the life of a structure.

Industries & Products

Common in railway, windmill fasteners, transmission towers, pipelines. Essential for civil engineering, construction, and heavy machinery.

Configuration & Capabilities

Customizable tanks with fume extraction, flux filtration, zinc dross management, and robotic loading arms.

Notable features:

- Pretreatment line with degrease, pickling, and fluxing stages

- Zinc kettles with ceramic or high-grade steel linings

- Fume enclosures with acid and flux mist handling

- Dross removal and zinc recovery systems

Explore Our Proven Track Record

From decorative trims to functional engine components, our surface finishing solutions have powered performance and elevated design.