Plastic Plating Line (PoP)

Plastic Plating (PoP) Systems for Decorative and Functional Finishing

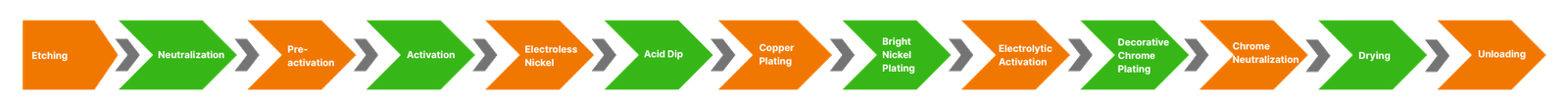

Suntech’s PoP systems offer full automation for metallizing ABS, PC-ABS, and other plastics with decorative or EMI-shielding coatings. From surface conditioning to copper/nickel/chrome layering, every stage is optimized for adhesion, uniformity, and efficiency.

We serve sectors like automotive interiors, electronics casings, and sanitary fittings with high-end chrome finishes.

Plastic Plating Machine Manufacturer delivering PoP systems for decorative and functional finishing.

As a trusted plastic plating machine manufacturer, Suntech delivers advanced PoP systems offering full automation for metallizing ABS, PC-ABS, and other plastics with decorative or EMI-shielding coatings. From surface conditioning to copper, nickel, and chrome layering, every stage is engineered for strong adhesion, coating uniformity, and process efficiency.

Our solutions support industries such as automotive interiors, electronics casings, and sanitary fittings, delivering high-end chrome finishes with consistent quality and long-term durability.

Purpose and Benefits

Plastic plating combines the benefits of lightweight polymer substrates with the durability and aesthetics of metallic coatings. It enables components to meet EMI/RFI shielding requirements or provide a premium chrome finish in consumer applications. The process ensures strong metallurgical adhesion, even on complex geometries.

Industries & Products

Used extensively in automotive interiors (dashboards, grilles, bezels, handles), electronics housings, sanitary fittings, and lifestyle products. Typical parts include ABS or PC-ABS components requiring decorative chrome or EMI/RFI shielding.

Configuration & Capabilities

Configurable for rack or barrel processing, with advanced handling systems for plastic substrates.

Notable features:

- Fully automated crane systems with PLC/SCADA control

- Multi-stage chemical conditioning tanks (etch to chrome)

- Optional vision systems for defect detection

- Closed-loop rinse water recycling

Purpose and Benefits

Plastic plating combines the benefits of lightweight polymer substrates with the durability and aesthetics of metallic coatings. It enables components to meet EMI/RFI shielding requirements or provide a premium chrome finish in consumer applications. The process ensures strong metallurgical adhesion, even on complex geometries.

Industries & Products

Used extensively in automotive interiors (dashboards, grilles, bezels, handles), electronics housings, sanitary fittings, and lifestyle products. Typical parts include ABS or PC-ABS components requiring decorative chrome or EMI/RFI shielding.

Configuration & Capabilities

Configurable for rack or barrel processing, with advanced handling systems for plastic substrates.

Notable features:

- Fully automated crane systems with PLC/SCADA control

- Multi-stage chemical conditioning tanks (etch to chrome)

- Optional vision systems for defect detection

- Closed-loop rinse water recycling

Explore Our Proven Track Record

From decorative trims to functional engine components, our surface finishing solutions have powered performance and elevated design.