Electropolishing Line

Automated Electropolishing Lines for Stainless Steel Finishing

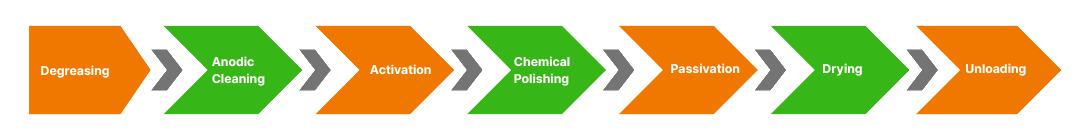

Suntech builds electropolishing systems for critical metal finishing applications, particularly where smoothness, brilliance, and passivation are essential. Our systems are ideal for industries such as medical, surgical tools, F&B processing, and precision components.

With recipe-controlled automation, we ensure consistent surface leveling, micro-deburring, and corrosion protection, all within a closed-loop environment.

Electro Polishing Plant with Automated Electropolishing Lines for Stainless Steel Finishing

Suntech builds electro polishing plants for critical metal finishing applications where surface smoothness, brilliance, and passivation are essential. As an experienced electro polishing plant solution provider, our systems are ideal for industries such as medical devices, surgical tools, food & beverage processing, and precision components.

With recipe-controlled automation, our electro polishing plant systems ensure consistent surface leveling, micro-deburring, and corrosion protection within a closed-loop environment, delivering repeatable quality and long-term performance.

Purpose and Benefits

Electropolishing not only improves the cosmetic finish but also passivates the surface, enhancing resistance to corrosion and microbial growth. The process removes microscopic peaks and embedded impurities, making surfaces smoother and more reflective. It is especially critical in sanitary and cleanroom applications, reducing contamination risk and facilitating easier cleaning.

Industries & Products

Widely used in medical and surgical tools, pharmaceutical processing tanks, aerospace parts, critical fasteners and cleanroom equipment. It’s also the preferred finishing for F&B and semiconductor-grade components.

Configuration & Capabilities

Suntech’s systems include precision DC power supplies, multi-zone temperature control, and PLC-based monitoring. Available in batch or inline configurations with optional ultrasonic-assisted pre-cleaning.

Notable features:

- Precision rectifiers with ripple < 2%

- Electrolyte heating and circulation systems for uniform polishing

- Optional ultrasonic degreasing and rinse tanks

- Stainless steel tanks with fume extraction

- SCADA-enabled process monitoring and data logging

Purpose and Benefits

Electropolishing not only improves the cosmetic finish but also passivates the surface, enhancing resistance to corrosion and microbial growth. The process removes microscopic peaks and embedded impurities, making surfaces smoother and more reflective. It is especially critical in sanitary and cleanroom applications, reducing contamination risk and facilitating easier cleaning.

Industries & Products

Widely used in medical and surgical tools, pharmaceutical processing tanks, aerospace parts, critical fasteners and cleanroom equipment. It’s also the preferred finishing for F&B and semiconductor-grade components.

Configuration & Capabilities

Suntech’s systems include precision DC power supplies, multi-zone temperature control, and PLC-based monitoring. Available in batch or inline configurations with optional ultrasonic-assisted pre-cleaning.

Notable features:

- Precision rectifiers with ripple < 2%

- Electrolyte heating and circulation systems for uniform polishing

- Optional ultrasonic degreasing and rinse tanks

- Stainless steel tanks with fume extraction

- SCADA-enabled process monitoring and data logging

Explore Our Proven Track Record

From decorative trims to functional engine components, our surface finishing solutions have powered performance and elevated design.