Aerospace

Aerospace Surface Treatment in India for High-Stakes Performance

The aerospace industry demands uncompromising quality, traceability, and safety. Suntech delivers aerospace surface treatment in India through advanced, automated solutions engineered for aerospace, defense, and MRO applications. Our systems support critical aircraft components with superior corrosion protection, material integrity, and compliance with international aviation standards—ensuring reliable performance in the most demanding environments.

Our Solution for Aerospace Industry

Chemical Surface Treatment Lines

Main Use Areas:

- Aircraft structural assemblies – Pre-treatment for painting and bonding

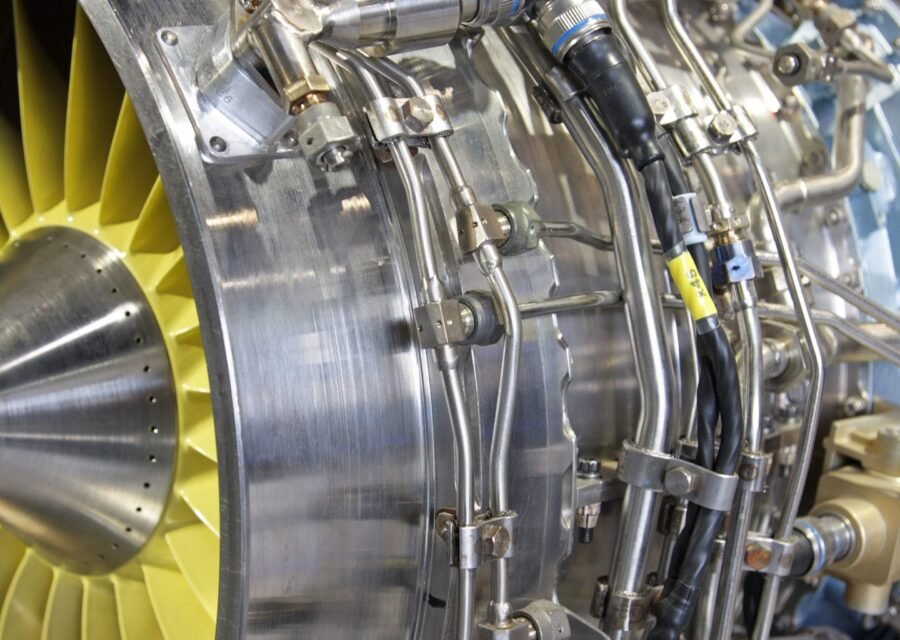

- Turbine engine housings – Corrosion resistance and surface prep

- Landing gear parts – Phosphating and passivation for durability

1. Electroplating

Key Aerospace Components:

➤ Fasteners – Zinc-nickel for corrosion and fatigue protection

➤ Connector pins & brackets – Conductive and anti-corrosive plating

2. Anodizing

Used mainly on aluminum parts:

➤ Wing panels and fuselage components – Corrosion protection

➤ Interior frames & ducts – Lightweight and long-lasting finish

3. Electropolishing

Stainless/titanium alloys:

➤ Turbine blades – Smoother airflow and high precision

➤ Hydraulic system tubes – Clean, rust-free internal surfaces

4. De-Embrittlement

Used On:

- ➤ Critical fasteners and engine bolts – To prevent hydrogen embrittlement

Our Solution for Aerospace Industry

Chemical Surface Treatment Lines

Main Aerospace Use Areas:

- Aircraft structural assemblies – Pre-treatment for painting and bonding

- Turbine engine housings – Corrosion resistance and surface prep

- Landing gear parts – Phosphating and passivation for durability

Electroplating / Anodizing / Electropolishing Lines

1. Electroplating

➤ Fasteners – Zinc-nickel for corrosion and fatigue protection

➤ Connector pins & brackets – Conductive and anti-corrosive plating

2. Anodizing

➤ Wing panels and fuselage components – Corrosion protection

➤ Interior frames & ducts – Lightweight and long-lasting finish

3. Electropolishing

➤ Turbine blades – Smoother airflow and high precision

➤Hydraulic system tubes – Clean, rust-free internal surfaces

De-Embrittlement

Used On:

- Critical fasteners and engine bolts – To prevent hydrogen embrittlement

Zinc Flake Coating & Galvanizing Systems

1. Zinc Flake Coating

➤ Bolts, screws, and fasteners – Especially wheel bolts, brake disc bolts

➤ Brake components – Anti-corrosion for caliper brackets, back plates

➤ Chassis and suspension parts – High corrosion environments

2. Hot-Dip Galvanizing

➤ Underbody structural members – Cross members, torsion beams

➤ Crash structures – High durability zones

➤ Battery trays – EV and hybrid vehicles

Explore Our Proven Track Record

From decorative trims to functional engine components, our surface finishing solutions have powered performance and elevated design.