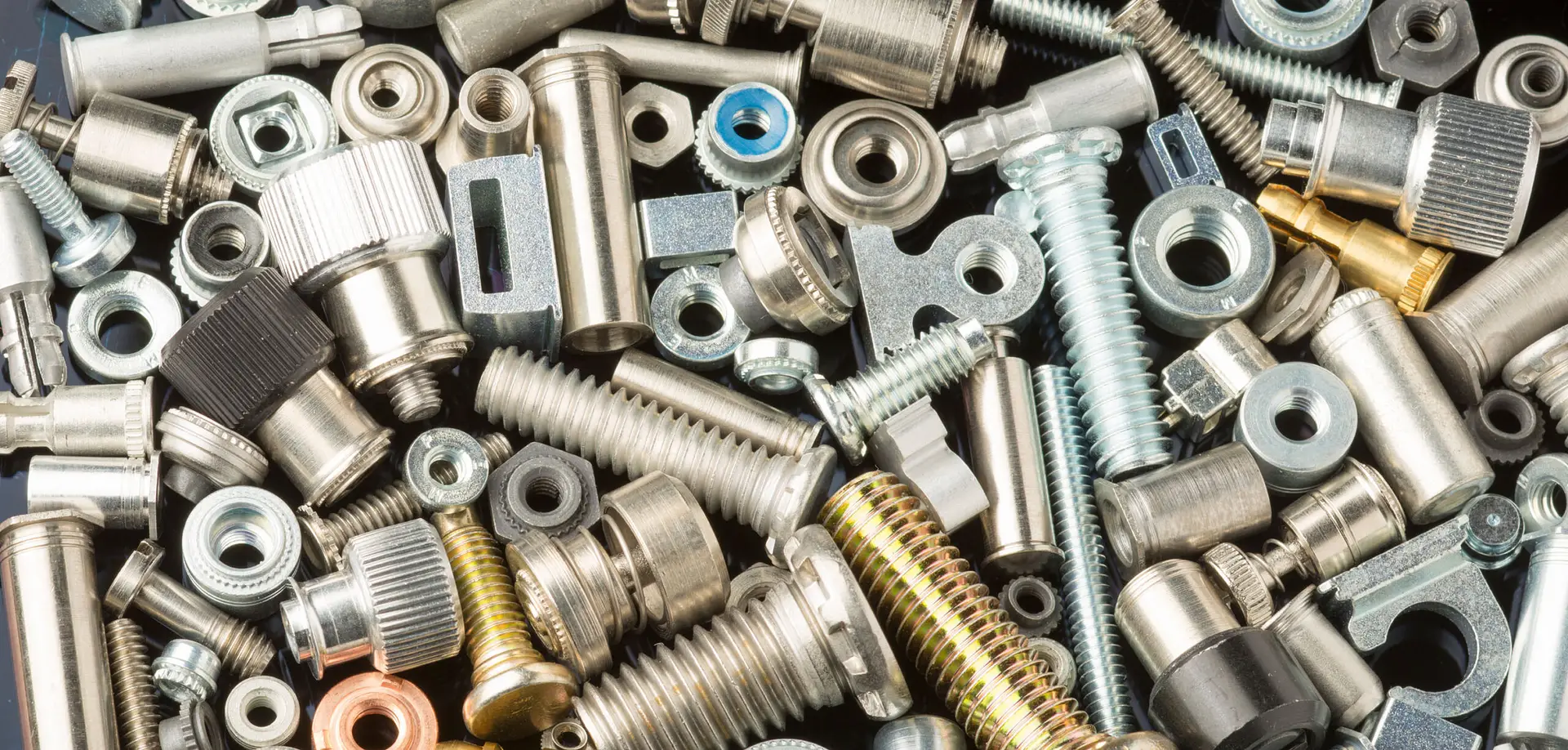

Fasteners & Precision Components

High-Performance Coatings for Critical Hardware

Fasteners, bolts, and precision machined parts need specialized treatments to ensure performance in automotive, aerospace, and construction. We provide coating systems designed for uniform coverage, corrosion protection, and fatigue resistance.

Our Solution for Fasteners & Precision Components

Chemical Surface Treatment Lines

Main Use Areas:

- Degreasing, pickling & phosphating of bolts, screws, shafts

- Activation for plating adhesion and torque enhancement via phosphating

1. Electroplating

Key Parts:

➤ Screws, studs, washers – Zinc/Zinc-nickel coatings

➤ Micro parts –Thin, uniform plating with tight tolerances

2. Electropolishing

Key Parts:

➤ Precision shafts, surgical screws, springs – Enhanced fit and finish

3. Passivation

Key Parts:

➤ Machined stainless parts – Long-term corrosion protection without adding coating

4. De-Embrittlement & Hydrogen Relief Lines

Used On:

- ➤ Post-hardened fasteners – Safety-critical components

Our Solution for Fasteners & Precision Components

Chemical Surface Treatment Lines

Main Use Areas:

- Degreasing, pickling & phosphating of bolts, screws, shafts

- Activation for plating adhesion and torque enhancement via phosphating

Electroplating / Electropolishing / Passivation

1. Electroplating

Key Parts:

➤Screws, studs, washers – Zinc/Zinc-nickel coatings

➤ Micro parts –Thin, uniform plating with tight tolerances

➤Screws, studs, washers – Zinc/Zinc-nickel coatings

➤ Micro parts –Thin, uniform plating with tight tolerances

2. Electropolishing

Key Parts:

➤Precision shafts, surgical screws, springs – Enhanced fit and finish

➤Precision shafts, surgical screws, springs – Enhanced fit and finish

3. Passivation

Key Parts:

➤ Machined stainless parts – Long-term corrosion protection without adding coating

➤ Machined stainless parts – Long-term corrosion protection without adding coating

De-Embrittlement & Hydrogen Relief Lines

Used On:

- Post-hardened fasteners – Safety-critical components

Zinc Flake Coating & Galvanizing Systems

1. Zinc Flake Coating

Critical Automotive Parts:

➤ Bolts, screws, and fasteners – Especially wheel bolts, brake disc bolts

➤ Brake components – Anti-corrosion for caliper brackets, back plates

➤ Chassis and suspension parts – High corrosion environments

➤ Bolts, screws, and fasteners – Especially wheel bolts, brake disc bolts

➤ Brake components – Anti-corrosion for caliper brackets, back plates

➤ Chassis and suspension parts – High corrosion environments

2. Hot-Dip Galvanizing

Important Structural Areas:

➤ Underbody structural members – Cross members, torsion beams

➤ Crash structures – High durability zones

➤ Battery trays – EV and hybrid vehicles

➤ Underbody structural members – Cross members, torsion beams

➤ Crash structures – High durability zones

➤ Battery trays – EV and hybrid vehicles

Explore Our Proven Track Record

From decorative trims to functional engine components, our surface finishing solutions have powered performance and elevated design.